-

Technology

-

News

-

Service Support

Technology

Aviation Industry

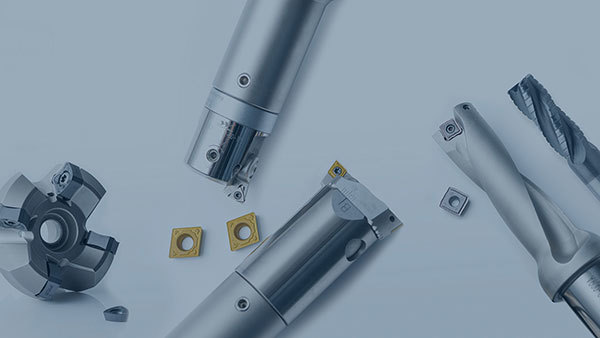

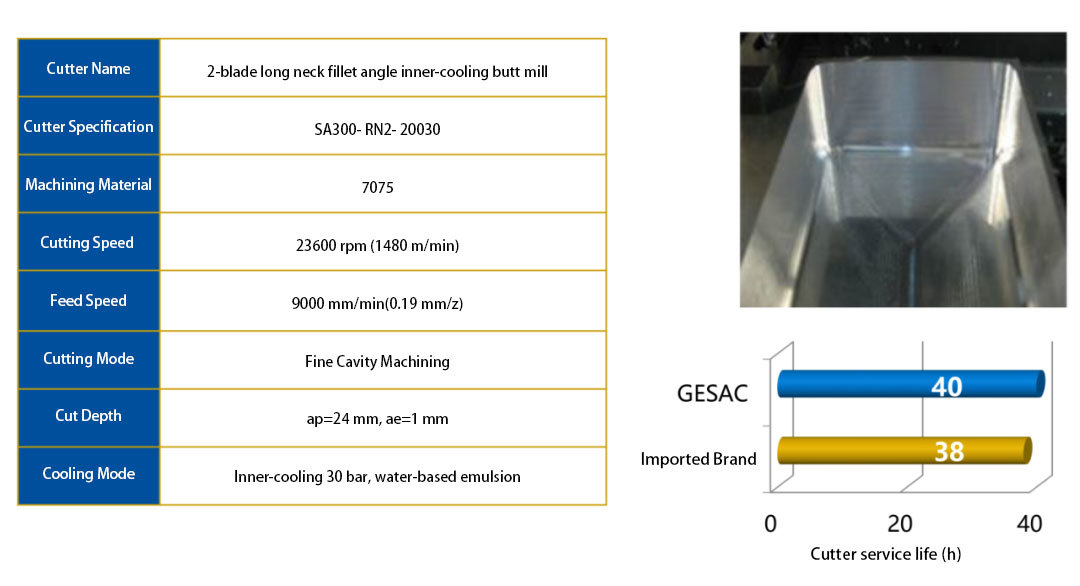

[Aviation industry] Machining solution to aluminum alloy frame

Industrial Machining Introduction

The integrated structure dominates the main load bearing structure of modern airplanes, which features complex structure, large material removal, accurate and surface quality requirement and long machining cycle. Cutting of these parts has urgent demands for realizing high efficient and correct machining. Main workpiece of the integrated structure is mainly made of aluminum alloy. Xiamen GESAC has mature machining plans for cavity milling, face milling and fine web machining of aluminum alloy structural parts.

Solution Diagram

Application Characteristics

Cutter diameter ranges from Ø6 mm to Ø32 mm, with optional Y-type inner-cooling design specification.

--Applicable for rough and fine machining

--Machining mode: cavity, side, face and plunge milling

--Machining material: applicable for aviation 7 series aluminum alloy material such as 7075 and 7050

--Dynamic balance: 25000 rpm, G=2.5 (ISO1940)

--Material removal rate: high speed type 1900 cc/min (D25, N=25000 rpm)

--Roughness: Ra0.4

--Roughness: Ra0.4

The case is the machining case of connecting angle box cavity in aerospace and aviation industry. Under the same working condition, our cutter has slightly longer service life and better workpiece surface quality than those of imported cutter.

Contact Us

Jimei Factory Address:

No. 52-60, Tianyang Road, North Industrial Zone, Jimei District, Xiamen City, Fujian Province China

Tongan Factory Address:

No. 1601-1629, Jiji Road, Industrial Concentration Zone, Tong'an District, Xiamen City, Fujian Province China

Haicang Factory Address:

No. 69, Dongfu West Road, Haicang District, Xiamen City, Fujian Province China

Email: gesac@cxtc.com

Scan and browse the mobile terminal

Copyright © Xiamen Golden Egret Special Alloy Co. Ltd. Powered by www.300.cn | SEO Tag