SH360

Integrated rigid steel machining butt mill

SH360 series rigid steel machining butt mill & SHM200 series small diameter deep machining butt mill

SH360 series rigid steel machining butt mill is applicable for general machining and partial high speed machining of HRC45 to 65 materials; SHM200 series small diameter deep machining butt mill is applicable for high speed machining of HRC45 to 65 materials. These two products feature high abrasive resistance, longer service life, better machining workpiece surface quality and higher cutter size accuracy, comparing with previous products.

SHM200 series small diameter deep machining butt mill

Technical Characteristics

Brand new generation of rigid steel coating technology

Our brand new generation of rigid steel coating has obviously improved hardness and oxidation resistance temperature, with hardness improved from 30 Gpa to 40 Gpa and top temperature from 1,000℃ to 1,200℃.

Precise grinding technology

Optimize cutter surface quality and improve machining workpiece surface quality

High stable grinding technology

Realize high accurate product and machining with high acceptability. The most representative property is to realize stable production of cutters with micro diameters

Application case

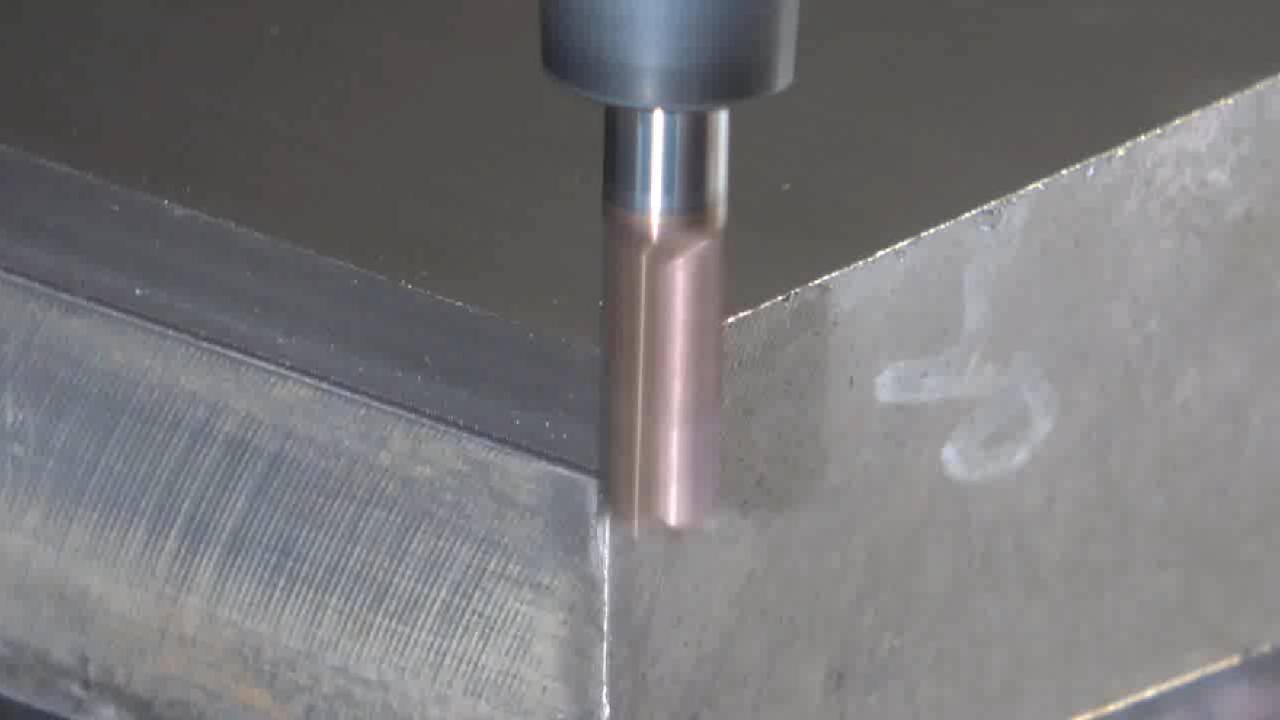

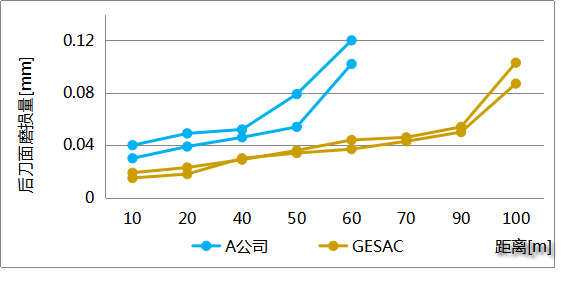

Case 1: SH360, D6 fine side milling, SKD11 (HRC60)

Cutter specification

SH360-S6-6-15-K / D6x15x50xd6

Machining material

SKD11(60HRC)

Parameters

n=8000RPM , F=3000mm/min , Ap=6.0mm , Ae=0.08mm

Cooling/Cutter handle

Air-cooled/Heat shrinkable cutter handle

Machining effect

According to comparison pictures of rear cutter face abrasion after 60 m machining under the same working condition, abrasion of GESAC cutter is 0.04 mm and that of Company A product exceeds 0.1 mm, unable to continue fine machining. GESAC brand new generation of rigid steel coating protects cutters effectively in machining and makes property of GESAC cutter superior to that of similar products of Company A by over 66%

Company A-machining 60 m

GESAC-machining 60 m

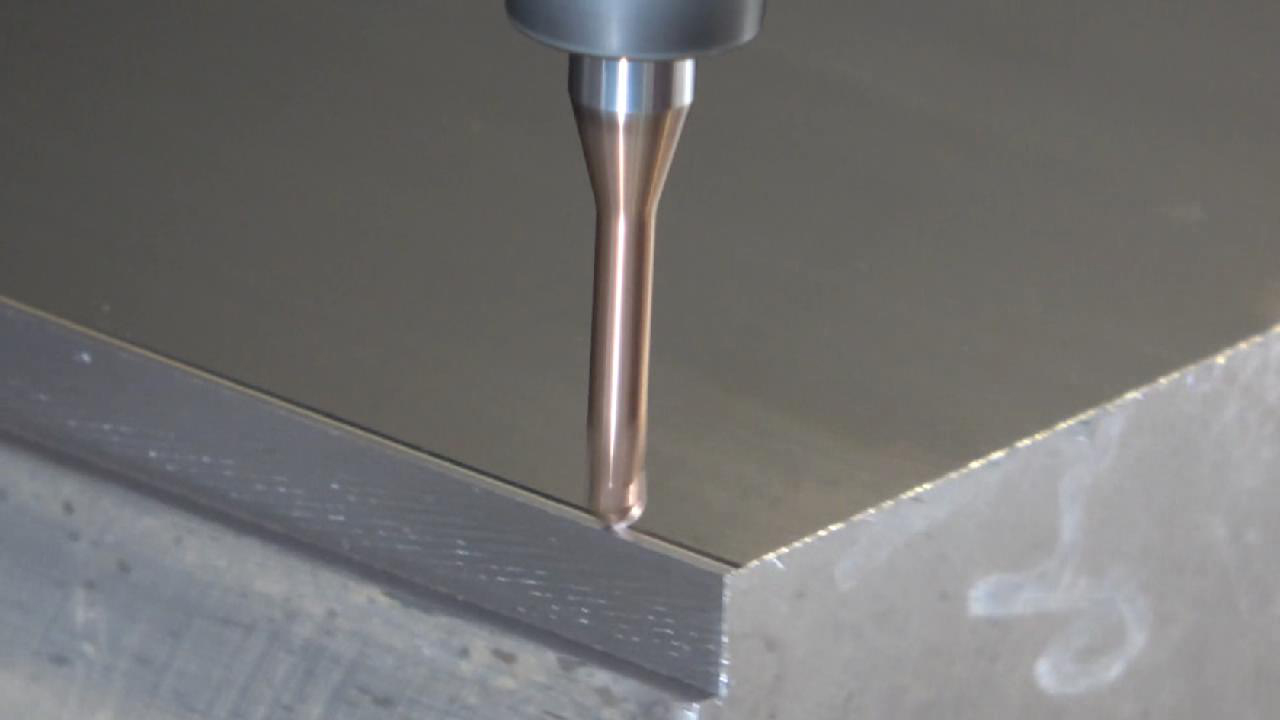

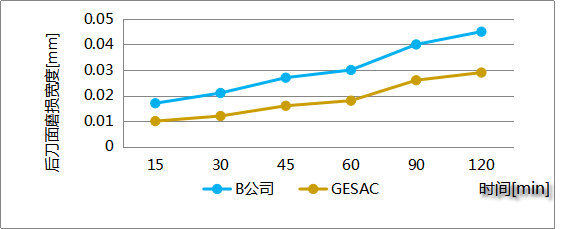

Case 2: SHM200, R1.5 fine face milling, SKD11 (HRC60)

Cutter specification

SHM200-BN2-3-13-K / R1.5x2.4x13

Machining material

SKD11(60HRC)

Parameter

n=11200RPM , F=1344mm/min , Ap=0.04mm , Ae=0.04mm

Cooling/Cutter handle

Air-cooled/Heat shrinkable cutter handle

Machining effect

According to comparison of rear cutter face abrasion after 120 min machining under the same working condition, abrasion of GESAC cutter is 0.027 mm and that of Company B cutter is up to 0.049 mm. Due to GESAC brand new generation of rigid steel coating property, property of GESAC cutter doubles that of similar products of Company B.

Technology