-

Technology

-

News

-

Service Support

GHDS

GHDS dual-spiral inner-cooling shallow hole drill

Product Characteristics

Dual-spiral inner-cooling structure technology-more proper structure and smooth chip removal; optimized inner and outer blade structure design-inner and outer blade has more balanced stress and stable machining; outgoing water of inner-cooling hole sprays front cutter face directly-more sufficient cooling, higher supporting strength of outer cutter holder; advanced surface treatment mode-eliminate drill surface stress, featuring green and environmental protection.

Application Fields

It is widely applied to automobile, energy, die, valve, general and engineering machinery industries.

Application Case

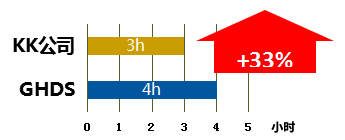

Case 1-valve bolt hole machining of valve industry

Cutter model: PQPMG110408-DP-GM3220

Cutter specification: GHD-350-3D-FC40-Q11S

Machining material: 16Mn (HRC28)

Cutting speed: Vc=200 m/min

Feed: fn=0.055 mm/rev

Drilling depth: 90 mm (through-hole)

Machining equipment: vertical machining center

Cooling mode: inner-cooling

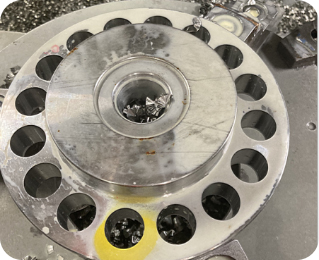

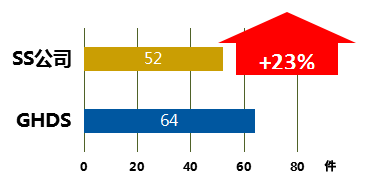

Case 2--Main front axle pin hole machining of automobile industry

Cutter model: PQPMG09T308-DP-GA4230

Cutter specification: GHD-320-4D-FC40-Q09S

Machining material: 42CrMo (HRC23-30)

Cutting speed: Vc=127 m/min

Feed: fn=0.12 mm/rev

Drilling depth: 102 mm (through-hole)

Machining equipment: vertical machining center

Cooling mode: inner-cooling

Technology

Contact Us

Jimei Factory Address:

No. 52-60, Tianyang Road, North Industrial Zone, Jimei District, Xiamen City, Fujian Province China

Tongan Factory Address:

No. 1601-1629, Jiji Road, Industrial Concentration Zone, Tong'an District, Xiamen City, Fujian Province China

Haicang Factory Address:

No. 69, Dongfu West Road, Haicang District, Xiamen City, Fujian Province China

Email: gesac@cxtc.com

Scan and browse the mobile terminal

Copyright © Xiamen Golden Egret Special Alloy Co. Ltd. Powered by www.300.cn | SEO Tag