The Xiamen Golden Heron G-PAK2023 New Product Launch Conference was successfully held, and the Silver Bird series made a significant debut!

2023-11-14

【Brief description】 In October, in this picturesque harvest season, on October 26, Xiamen Jinlu G-PAK2023 new product launch conference was successfully held, and it was reported live through the metal processing all-media platform. Offline, many users and partners gathered together; Online, the audience from Tiannan and Haibei also paid great attention.

In October, in this picturesque harvest season, on October 26, Xiamen Jinlu G-PAK2023 new product launch conference was successfully held, and it was reported live through the metal processing all-media platform. Offline, many users and partners gathered together; Online, the audience from Tiannan and Haibei also paid great attention.

As a well-known supplier of tungsten powder, cemented carbide and cutting tools, Xiamen Jinlu Special Alloy Co., Ltd. (hereinafter referred to as "Xiamen Jinlu") adheres to the principle of deep cultivation of terminals, lean quality and innovative services, and has launched more and more new products with independent intellectual property rights and won market praise. G-PAK2023 has a special significance for Xiamen Golden Heron, this year coincides with the 10th anniversary of G-PAK, in the course of ten years of development, Xiamen Golden Heron wins users with products and explores opportunities with innovation.

More than 600 guests from the association, government leaders, experts and scholars from universities, end users and partners came to the press conference, and the conference received more than 30,000 people's attention online. At the same time, the launch of the "Silver Sparrow" series of titanium alloy milling tools demonstrated the unremitting tackling and excellent achievements of Xiamen Jinlu cutting tools from scratch, from there to refinement, and from refinement to perfection in the past ten years.

At the beginning of the meeting, Huang Changgeng, chairman of Xiamen Tungsten Industry Co., Ltd., first expressed a warm welcome to all the guests. In his speech, he said that as a core member of Xiamen tungsten industry, Xiamen Jinlu focuses on the research and development, production and sales of tungsten series products, and provides competitive tungsten series products and services for global users by virtue of the integrated R&D technology of the complete tungsten industry chain and the management concept of realistic and innovative. With the mission of providing cost reduction, efficiency increase and all-round services for end users, Xiamen Jinlu has gradually developed from a manufacturer of metal cutting tools to a provider of overall processing solutions in the industry. Looking forward to the future, Xiamen Jinlu will continue to adhere to technological innovation as the core driving force, actively develop innovative products, strive to build a professional and efficient cutting technology service platform, and make greater contributions to the high-speed and high-quality development of China's cutting tool industry and China's manufacturing industry.

Huang Changgeng, Chairman of Xiamen Tungsten Industry Co., Ltd., delivered a welcome speech

Mao Yufeng, president of China Machine Tool Industry Association, also delivered a speech for the new product launch, he said in his speech that in the past ten years, Xiamen Jinlu as a typical representative of China's cutting tool brand has devoted itself to research, product technology innovation, rapid development, in the increasingly fierce competitive environment, has been highly recognized by the market, but also to the world to show the strength and confidence of Chinese manufacturing. As a typical representative of China's cutting tool enterprises, we look forward to seeing Xiamen Golden Egret continue to adhere to independent research and development and innovation, and introduce more and better products to the market; Continue to adhere to the market strategy of intensive cultivation terminals, and provide more users with more complete and efficient processing solutions; We will continue to adhere to the path of high-quality development, jointly promote the high-quality development of China's cutting tool industry, and contribute China's strength to the high-quality development of the global manufacturing industry.

Mao Yufeng, President of China Machine Tool Industry Association, delivered a speech

From Ruishi Jin Gong I Dao Xian Heron

To pick up the years and win the future together

So what exactly is the G-PAK, which is already in its 10th anniversary? Zou Lingli, general manager of Xiamen Jinlu Cutting Tools Division, gave a clear answer:

- G-PAK is the precipitation of Xiamen Golden Egret technology accumulation;

- G-PAK is an independent innovation product of Xiamen Golden Hero;

- G-PAK is the crystallization of the wisdom of the Xiamen Golden Egret team;

- G-PAK is the friendship of Xiamen Golden Egret partners;

- G-PAK is a grand event for the cutting tool industry.

Zou Lingli, general manager of Xiamen Jinlu Cutting Tools Division

In order to help users reduce processing costs, improve production efficiency, improve processing quality, optimize tool inventory, shorten procurement time, etc., Xiamen Jinlu has been working hard for ten years, constantly innovating, and constantly breaking through and upgrading technology and products, and has now been able to provide users with high-quality cutting tools, better services, and overall solutions for some parts.

In the future, Xiamen Golden Egret will continue to build seven core competitiveness: basic research, application technology, resource integration, solution services, product delivery, intelligent manufacturing and digital management, realize the transformation from a tool product manufacturer to a comprehensive tool service provider, and work with industry partners to build an industry ecosystem, go hand in hand and win the future!

Titanium alloy machining

Silver Sparrow shows its skills

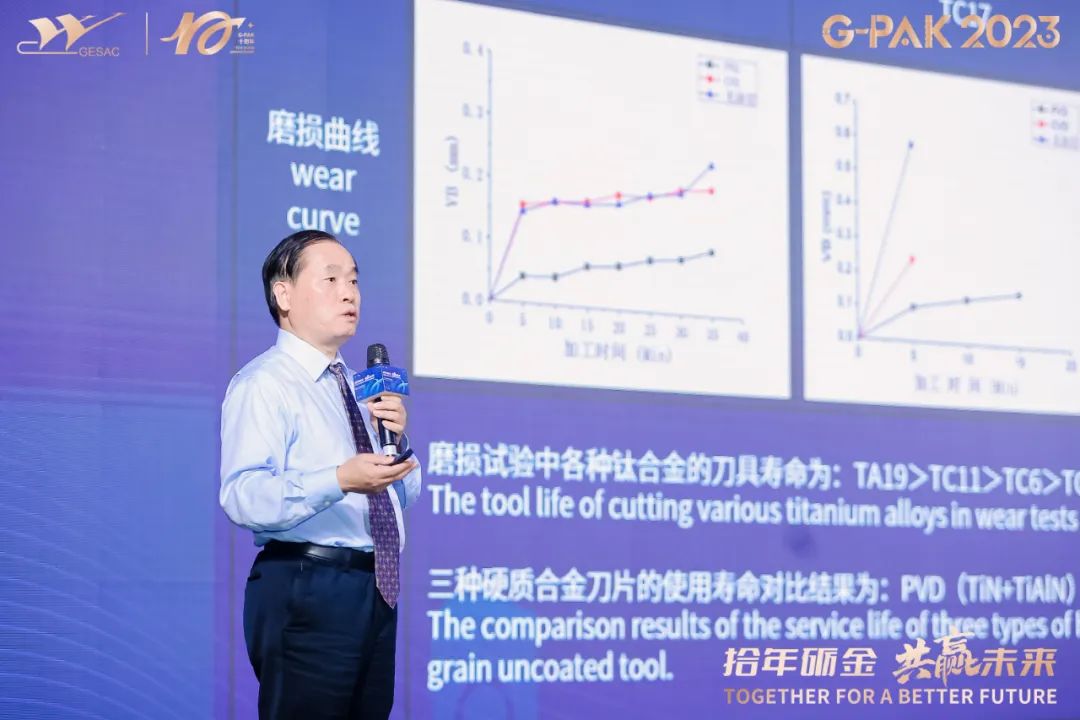

In the cutting of titanium alloy, it is very difficult to process because of its characteristics of low plasticity, large rebound, high chemical activity at high temperature, large friction coefficient, small elastic modulus and small thermal conductivity. Chen Ming, a professor and doctoral supervisor at Shanghai Jiao Tong University, shared that titanium alloy materials are difficult to cut, mainly because of the high cutting temperature, serious sticking of the knife, large cutting force, and serious chipping and cold hardness. For the cutting of titanium alloys, the research and development of tools should establish a positive research and development idea, from tool measurement and detection, modeling, cutting experiment verification, to structural optimization, tool optimization and preparation, cutting performance evaluation and production line on-site testing. He also pointed out that the future development direction of titanium processing tools will be more efficient, higher life, more intelligent and more economical.

Chen Ming, professor and doctoral supervisor of Shanghai Jiao Tong University

The blockbuster new product launched by Xiamen Jinlu on G-PAK2023 is the Yinque series titanium alloy milling tools developed for the pain points and difficulties of titanium alloy processing. Silver Bird series knives are named because of their unique silver-white anti-adhesion coating on the surface, which is like the silver bird in ancient Chinese mythology, which means that it is not afraid of difficulties, and the armor is sharp, which can solve the problem of titanium alloy processing.

In view of the common pain points such as low titanium processing efficiency, long production cycle and short tool life, it is not simply the factors that affect the efficiency improvement (processing equipment, cutting fluid, blank, workpiece clamping, process plan and tool selection) that are optimized or correct. Hong Peiqiang, manager of Xiamen Jinlu aerospace industry, took the short beam of aviation parts as an example, and shared that the efficiency improvement should be based on the needs of users, through a reasonable processing technology plan, so that the parts processing is faster and more reasonable; Maximize machining efficiency with the right tool selection. According to examples, he also introduced Xiamen Jinlu's solutions to the three cruxes of efficiency improvement in the processing of titanium alloy structural parts: insufficient rigidity, margin setting and tool selection.

Hong Peiqiang, manager of Xiamen Jinlu aerospace industry, explained the processing solution of titanium alloy structural parts

As a further upgrade of Xiamen Jinlu GEFOTECH® technology, the "Yinque" series grade has achieved a major breakthrough in the aspects of tool matrix, coating and surface edge treatment, forming a new GS*71 series grade, which solves the problems of easy stickiness, abnormal chipping and short life of titanium alloy in the machining process. "Silver Sparrow" series of titanium alloy milling tool grades, with excellent anti-adhesion technology, and matched with the special matrix for anti-collapse, have excellent performance in fine to semi-fine medium and low speed machining, which can improve tool life and processing efficiency.

Zheng Aiqin, manager of Xiamen Jinlu Material Technology Department, explained the "Silver Bird" series of titanium alloy milling tools

Titanium alloy machining end mill with high efficiency + long life

The first new product is the "Silver Sparrow" series of titanium alloy integral milling tools, which are designed and developed for machining problems such as poor resonance, low cutting efficiency and poor chip removal performance. The launch of the "Silver Sparrow" series of titanium alloy machining end mills ST300 for machining problems for tool optimization and innovation, can achieve the overall suppression of bad resonance, improve chip removal performance, and through the new titanium alloy processing special grade, can improve wear resistance, improve tool life, and effectively solve customer problems.

Li Yousheng, manager of the product development department of Xiamen Jinlu, explained the "Yinque" series of titanium alloy integral milling tools, titanium alloy indexable milling cutters, and efficient + high precision

Another new product - "Silver Sparrow" series of titanium alloy indexable milling tools, including titanium alloy fast feed milling and titanium alloy shoulder milling. Titanium alloy fast feed milling SOM(E)T+MKT113&213 can ensure higher feed and higher processing efficiency when the size of the depth of cut; With the new SM geometry and ST geometry, the arc strength of the cutting edge is enhanced and the arc cutting edge is used to effectively reduce insert chipping and achieve higher strength. Titanium alloy shoulder milling ADGT+MET190 can effectively solve the problem of poor verticality and obvious joint marks in the process of titanium alloy machining, using C-shaped edge type, there are 9 kinds of tip fillet specifications to choose from, and high precision can be achieved by using a suitable linear angle.

Yuan Wenhao, the person in charge of the development of Xiamen Jinlu indexable tools, explained the "Silver Sparrow" series of titanium alloy indexable milling tools

The golden heron parlor talks about the industry

As a special planning link of G-PAK2023, the Golden Egret Lounge invited leaders of industry associations, representatives of end users, representatives of tool manufacturing enterprises, representatives of machine tool manufacturing enterprises and representatives of dealers to discuss the processing solutions of difficult-to-machine materials such as titanium alloys.

Xiamen Jinlu Jiang Tao, general manager said that he is optimistic about the future development prospects of titanium alloy materials, but there are still some difficulties in material processing. Tang Chao, deputy general manager of the business department of Shandong Halma Machinery Technology Co., Ltd., said that as an end user, they attach great importance to the overall solution ability and rapid response ability of tool manufacturing enterprises, and gave affirmation of the cooperation effect with Xiamen Golden Heron. Zha Guobing, Secretary-General of the Tools Branch of China Machine Tool Industry Association, proposed that the processing solutions represented by difficult-to-machine materials can be said to be the embodiment of the core competitiveness of enterprises. Zhongsheng, general manager of the rapid manufacturing business department of Beijing Jingdiao Technology Group, said that he very much agrees with the idea of providing users with overall solutions, and users no longer only need a single equipment. As a representative of the dealer, the general manager of Flavio, Brazil Jinlu, and the general manager of Xi'an Wanwei Machinery Manufacturing Co., Ltd., Tonggang, both said that they would prepare targeted solutions based on the understanding and needs of users to better serve customers.

Jiang Tao, general manager of Xiamen Golden Egret, expressed his views in the Golden Egret meeting room

Through this feast of ideas, more thinking in the ecosystem has been triggered, and users will continue to be deeply cultivated to create more value for users in order to seek better enterprise development.

The Development Advisory Board helps development

Jiang Tao, general manager of Xiamen Golden Heron, said that the original intention of the establishment of the cutting tool development advisory committee is to solve the problems and difficulties in the development of the domestic cutting tool industry, and the experts of the committee can work together to promote the development of the cutting tool industry, and can also give guidance to the development of Xiamen Jinlu cutting tool division and promote the communication and exchange of upstream and downstream enterprises. Wu Gaojiao, President of Xiamen Tungsten Industry and Chairman of Xiamen Jinlu, read out the list of the first advisory members of the Xiamen Jinlu Cutting Tools Development Advisory Committee, including Mao Yufeng, President of China Machine Tool Industry Association, and Beijing Jingdiao Technology Group Co., Ltd., a total of 8 individual members and 18 enterprise members. We look forward to the experts of the Future Development Advisory Committee to provide advice on the development of the industry and enterprises.

Wu Gaojiao, President of Xiamen Tungsten Industry and Chairman of Xiamen Golden Egret, read out the list of the first advisory members of the Development Advisory Committee

At the G-PAK2023 new product launch conference, Xiamen Jinlu focused on launching three series of new titanium alloy processing products, after the explanation of the person in charge of new product research and development, many technical advantages to solve the processing pain points and difficulties have been more clearly displayed, which fully reflects the rich technical heritage and the latest research and development achievements of Xiamen Jinlu. Whether it is in the exchange at the conference site or the online interaction, everyone has given great affirmation to the R&D and innovation of Xiamen Golden Egret. As a leader in domestic knife brands, Xiamen Jinlu has set a benchmark in independent innovation. In the future, I believe that they will continue to increase R&D investment, overcome more technical problems, bring higher quality tool products and more comprehensive overall solutions, and help users continue to improve their competitiveness.

RELATED NEWS

14

2023-11

Release Time:2023-11-14

Pageviews: